Specialty Hoppers

Specialty hoppers for brewers; as with all of our brewery grain handling solutions, they come made-to-order with turn-key integration & service.

Specialty hoppers are placed in-line with malt storage equipment and allow brewers to add specialty malt to the conveying line as needed. Specialty hoppers are necessary when the mill lacks a dump port or is not easily accessible.

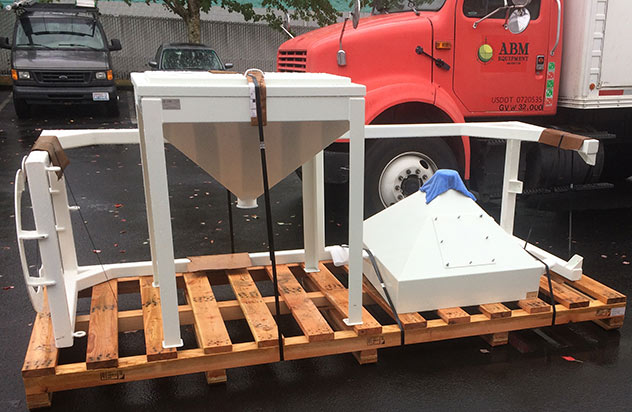

Standard outlets are 4″ in diameter, which is plenty for most applications. Outlets can be stepped up to 6″ when using pre-milled malt (which tends to bridge) or when greater flow is required.

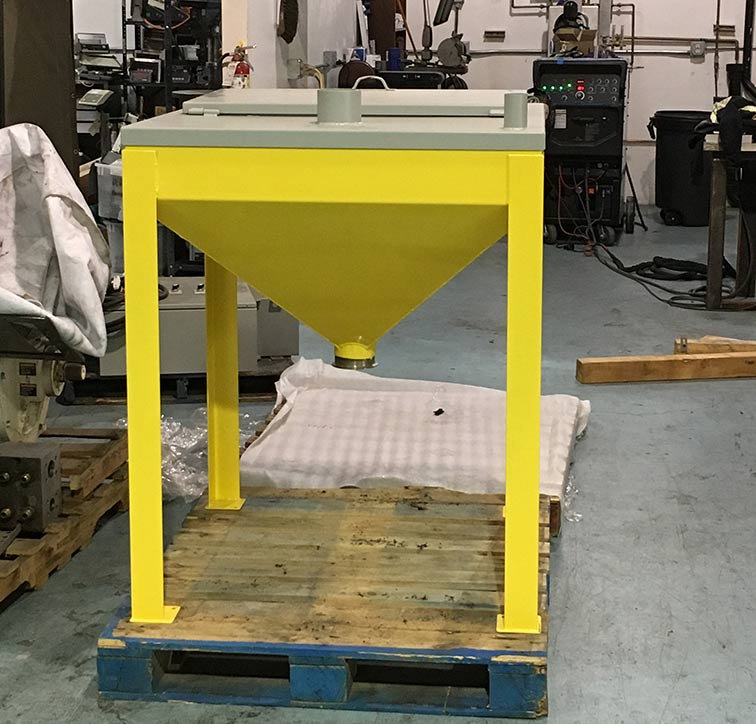

Most commonly made with powder-coated carbon steel, our specialty hoppers are available in stainless wash-down options for placement near brewing tanks.

Specialty hoppers can be as big as needed, but they commonly come in 150-170 lbs capacities to allow addition of 3 bags at a time. Every specialty hopper comes with a 2″ dust port for attachment of dust collection systems (or a dust sock), a grate to catch the occasional screw-driver or key-chain that wants to see what’s going on in your mill, and a heavy door to control dust.

Specialty hoppers can be made in any color or shape and can be outfitted with pneumatic gates so you can pre-load recipes. The gate is self-compressing and only requires a 110 AC/DC connection.

Visit our instagram @grain_handling for more pictures