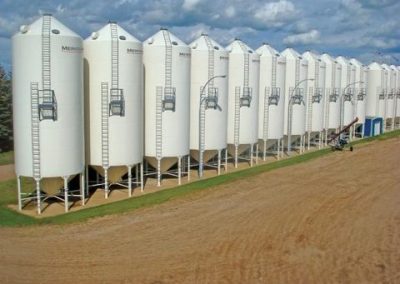

Brewery Silos

Ingress & egress free, built to last

Brewery silos are smooth-wall silos with custom discharges to prevent infestations. They’re available in powder-coated or stainless steel and with various flow-assists for tight spaces. As usual, they’re made-to-order with turn-key integration & service.

Fully Cured Powder Coating

Top-quality powder coating protects the silo, the product, and the appearance of the facility.

Custom-Built

Each unit is designed for the brewery or distillery’s brand, local climate, seismic area, and municipal codes for ease of permitting.

Dust-Tight Discharge Gates

Our custom solution eliminates leakage, protecting grain from moisture and resisting infestation.

Single-Piece welded builds

Bolt-less and seamless interiors increase longevity and resist hang-ups and ingress of contaminants.

Silos allow significant savings on grain and typically generate positive ROI for breweries at about 2000 BBLs annual production. This is because, aside from the significant savings of being able to buy grain in bulk, silos present a few other benefits. They allow grain/malt to be stored for longer, the automated systems save a lot of money in labor hours, and although silos can be placed inside when needed, they typically free up a lot of floorspace by taking the storage outdoors. You can convey from silos using augers, chain-disks, or pneumatics.

Corrugated-Wall Silos

Corrugated silos are used when they will be sheltered from the elements, budgets are tight, and they will not be filled pneumatically. But because of the nature of their materials and design, they should only be used in a pinch. This is because corrugated silos are meant to be mechanically filled, not pumped into by a grain truck. The fluctuating pressure from pneumatics (not to mention the expanding and contracting caused by temperature variations) cause bolts to come out and leaks to form. Corrugated-wall silos also tend to let more moisture in overall, lose the inner galvanization to attrition, and get grain stuck in nooks and crannies.

Smooth-Wall Silos

Articles abound on the difference between bolt-together smooth and corrugated wall silos, but the nature of bolt-together is the problem. The main benefit of smooth-walled silos is they can come manufactured in a single piece. Single-piece, smooth-walled silos are the best solution for brewers, hands-down. Grain doesn’t get stuck, there’s more protection from moisture, and, because no screws are involved, a number of other options are available such as vibratory flow-assists for applications where the outlet slope must be under 30°.

The ABM Advantage

Made-to-order silos can fit nearly any space whether that means custom dimensions, materials, components, or features. Our silos come with a number of advantages for the brewery world including:

- Leak/dust-free discharge gates

- Level indicators and/or sight glasses

- Strategies for avoiding municipal restrictions

Our silos are made in North America with high-grade steel & components and feature:

- High-quality interior and external powder coating

- Tubing legs and bracing for cleanliness and durability

- Fill pipes with radius elbows and scroll boxes for reduced product damage

- Horizontal bands for full structural support

- Vent lines to reduce dust buildup on the roof and surrounding surfaces

- Filter bags for the vent line

- Top non-venting manholes

- Enclosed auger boots for product integrity and cleanliness

Silos are made-to-order to accommodate height or footprint restrictions.

OPTIONS:

- Dust collection mounts

- Fall arrest systems

- Caged ladders & high-grip railing

- Flow-assists

- Vibratory

- Air

- Bottom access-hatch

- Laterally-supported foundation

- Glass viewport